SPM

The configuration allows you to build production systems of the classic ERP circuit (without accounting) using various management concepts: MRP II, SCM, Lean, APS, updated "Novocherkassk Rodova system"

For medium-sized and large enterprises (from hundreds to 10+ thousand people), including those with a distributed structure.

Конфигурация позволяет строить производственные системы классического ERP контура (без бухгалтерии) с использованием различных концепций управления: MRP-II, SCM, Lean, APS обновленная «Новочеркасская система Родова»

For medium-sized and large enterprises (from hundreds to 10+ thousand people), including those with a distributed structure.

Distinctive features and methodological basis of SPM

- The basic management object in the SPM

The composition of products (SI): design, technological, production (order-based). The specification, plus the packing route, as well as (if any) the technical process — allow you to calculate the production and supply plan.

- The SPM starts working on data that exists at the time of implementation.

- Various planning algorithms are implemented, combined based on the needs of the enterprise.

- Planning algorithm for demand / output modeling and capacity balancing based on aggregated and transformed product structures in the system.

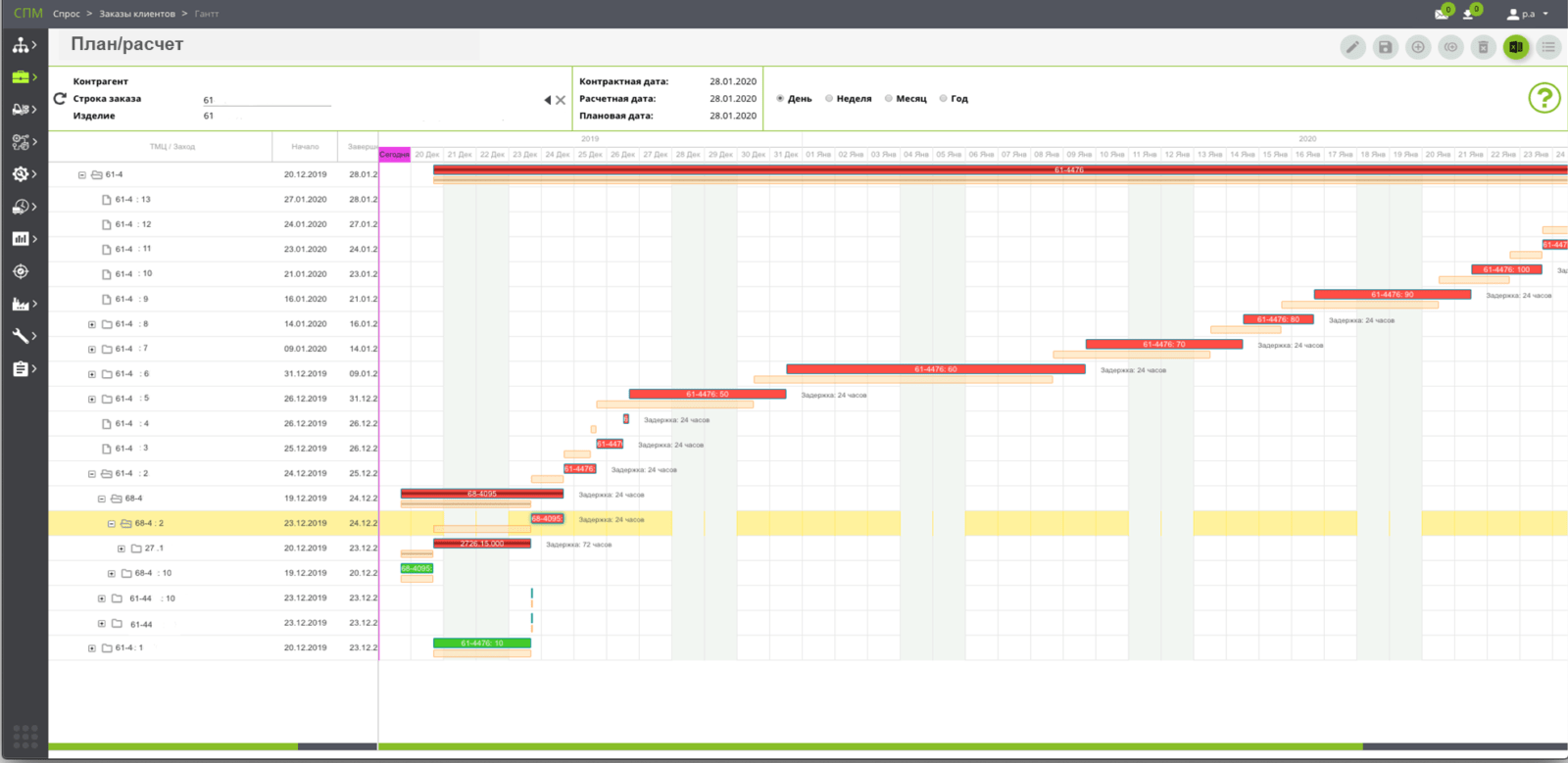

- Сетевой APS алгоритм для позаказного планирования с использованием TOC and Lean инструментария (особое планирование узких мест, вытягивание под узкие места / заказы, ограничения запуска, расчет оптимальных партий, и прочее), с мягким/жестким/условным (по направлениям спроса / заказчика) распределением запасов по производственной цепочке.

- MRP, MRP-C (MRP Capacitated) algorithms, including those with consolidation of production / supply batches, planning by Re-order point.

- In the SPM, there are always at least two variants of the plan at the same time: "directive" and "calculated".

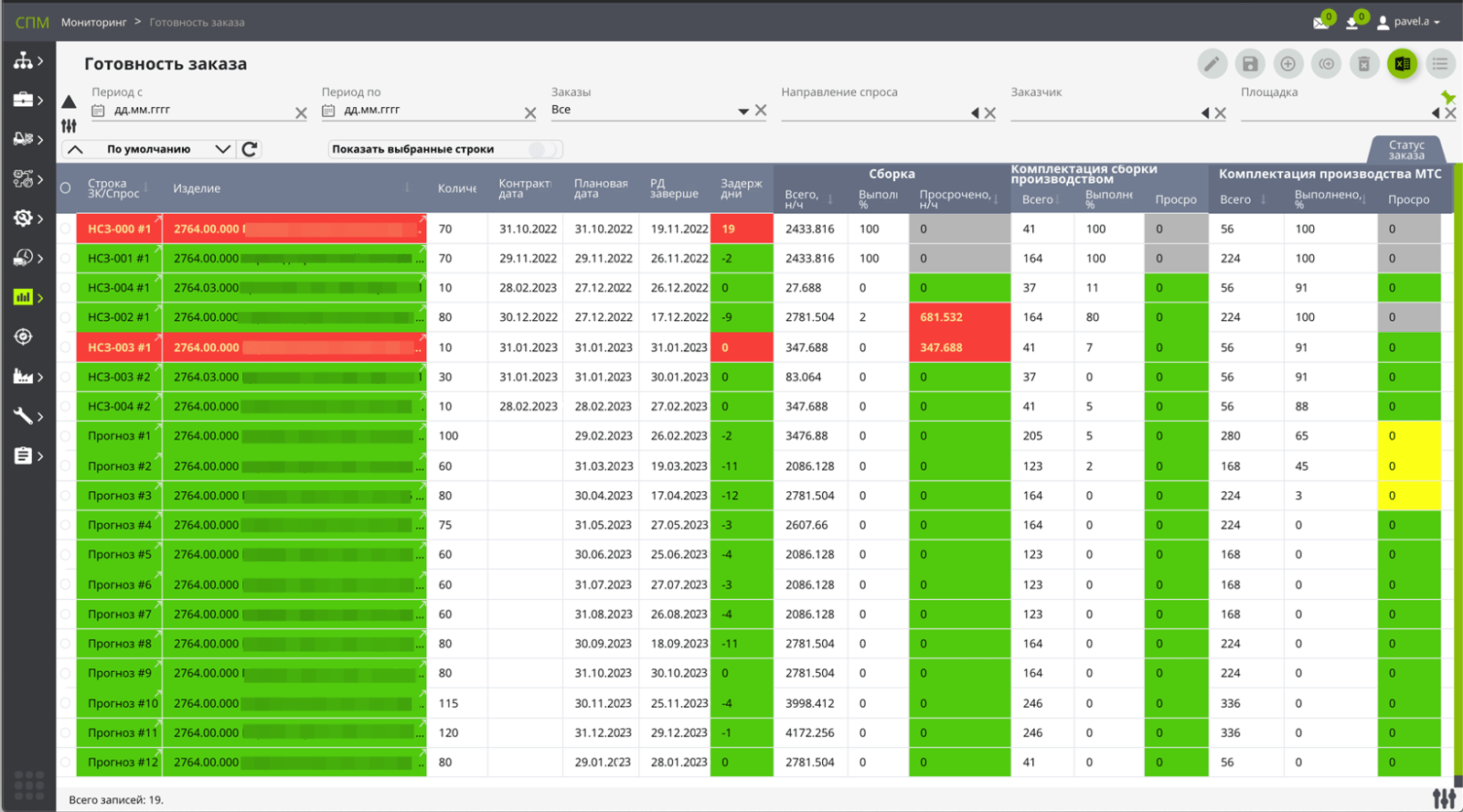

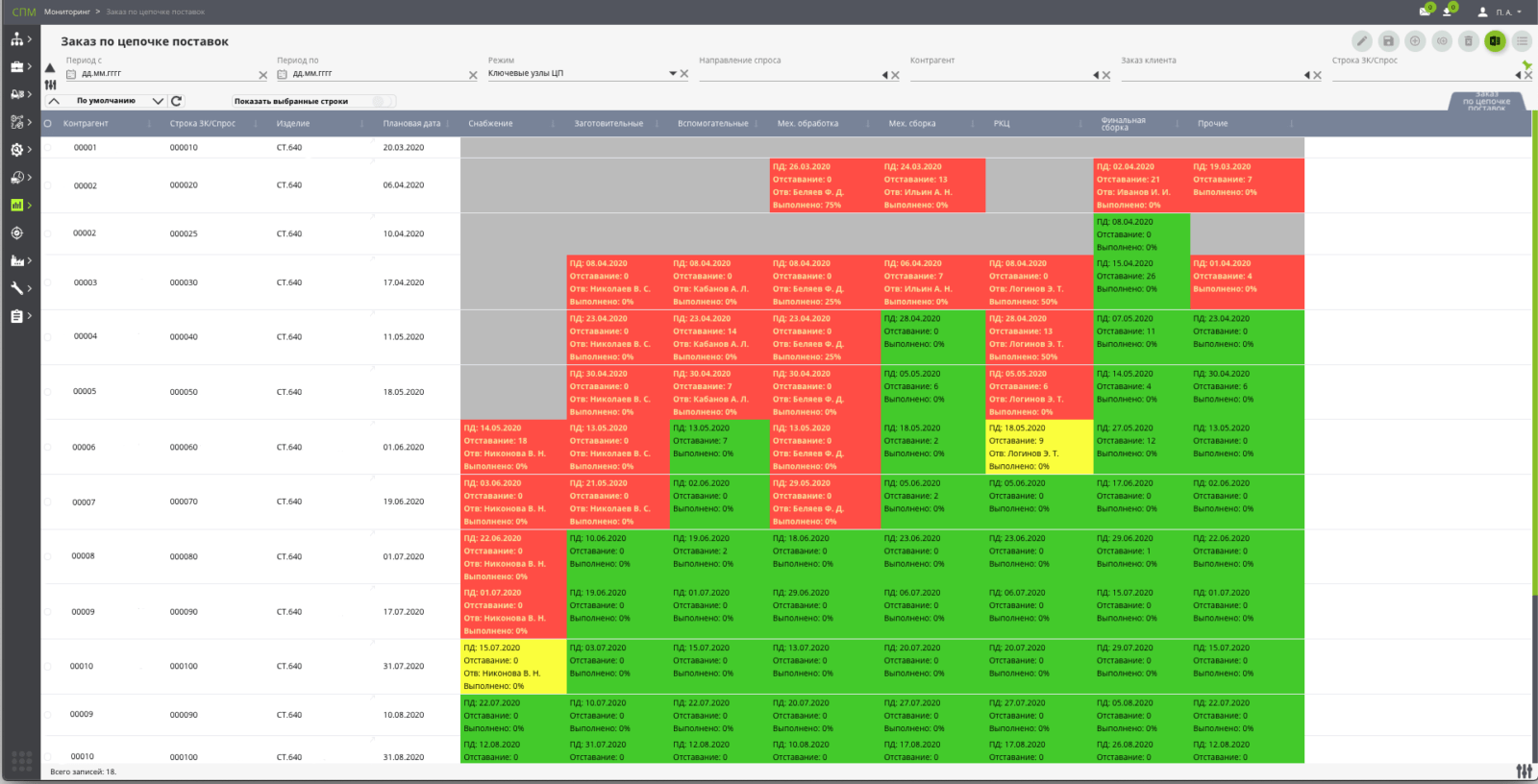

Visualization of deviations from target values, with color indication of criticality (red-green-yellow-blue), allows managers of departments and enterprises to concentrate on managing deviations.

- СПМ поддерживает Lean инструменты планирования и управления:

Kanban management, supermarket configuration, pull-out planning, clock planning, quick accounting of Kanban products Assembly units, визуализацию и прочее.

- Control and organization of feedback.

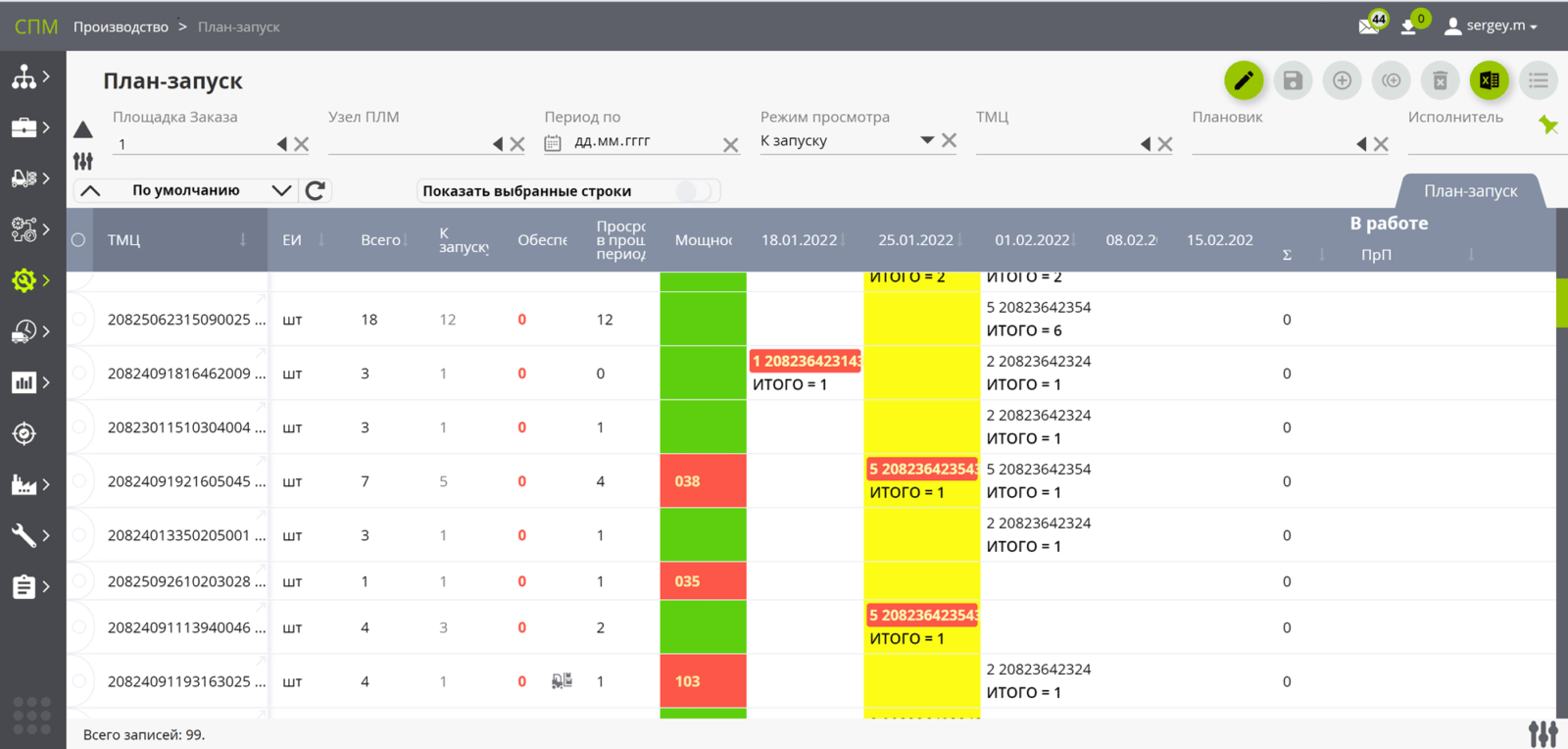

- Prioritization of production / purchase / relocation tasks calculated according to the established rules (critical ratio, early / late start / end date, etc.).

- On-line visualization: what happens to tasks / orders at levels ranging from parts to nodes, and the entire order. Color indication of deviations of the directive (target) plan from the current calculated one.

- Full support for remote work.

All on-screen forms work in web browsers. Including on mobile devices.

For in-shop management, inventory management, special forms for mobile devices have been developed, with the ability to scan barcodes / QR codes in a standard way and the functions of mobile devices.

Synchronized production–supply planning

- Planning both for products with mastered compositions (specifications, routes) and for those being developed (with temporarily simplified compositions of flourishes and production stages of the "development" type KTD") products.

- Prioritization in inventory allocation, WIP, arrivals, launch/release (several subordinate prioritization levels).

- Planning - order-based, with hard/soft/conditional distribution of material stocks, PKI, WIP and expected arrivals for orders.

- Different planning models and algorithms for different types of production/processing operations (final assembly, conveyor/posts, aggregate assembly/welding, mechanical processing and mechanical assembly, billet / stamping).

- Fast and constant (nightly) synchronization of plan/fact (planning back and forth along the entire production and logistics chain: transfer to the customer, testing and refinement, final assembly, inter-factory cooperation, supply).

- Possibility of on-line incremental recalculation of plans, taking into account changes in orders, the fact of production, rejected products, etc.

- Fast overall planning of large amounts of data (dozens of levels of nesting, hundreds of thousands of components in product compositions).

- On-line calculation of the production time of a specific product.

Моделирование и балансировка выпуска

- Моделирование выпуска по тактам и узким местам производственной цепочки.

- Автоматическое / ручное формирование плана выпуска на основании заказов, прогноза, по различным алгоритмам. В т. ч. на сборки в глубине состава изделия (честная реализация «Сборка-под-заказ»). С разбивкой / консолидацией заказов «по выпускам».

- Балансировка мощностей по цикловым графикам сборки, по загрузке ключевых переделов.

- Свой пул объектов и данных, позволяющий моделировать отдельно, без прямого влияния на оперативный план.

- Ресурсные составы и маршруты для моделирования.

- Прогнозное распределение изделий / вариантов исполнения по групповой позиции долгосрочного плана.

- Графики ресурсов и др.

- Возможность переноса плана выпуска / нового графика работы ресурсов после моделирования в основной план.

- The ability to use the built plan for flexible budgeting of production and deliveries.

Main production management

- Clear visual and automatic prioritization of starts / works.

- Flattening ПСИ, reducing the number of production and accounting objects through Phantoms, Auto-writing back and forth.

- Different levels of management: inter-shop / inter-stage / intra-shop (intra-stage).

- Various management objects are Production tasks (batches) of the following types: "Machine kit", "Route Map", "Assembly data sheet", "Kanban", "Assembly task".

- Intra-shop planning and management: manual / automated distribution of work by equipment / teams; manual / automatic queue management.

- The use of digital input tools to ensure the efficiency and accuracy of recording the progress of production: the use of barcoding, data collection kiosks, mobile terminals and tablets.

MTS and Inventory Management

- Automatic formation of an order-by-order plan synchronized with the release and production МТС.

- Visual and simple Launch management - formation of orders to suppliers.

- Supply management by user-defined delivery route (stages).

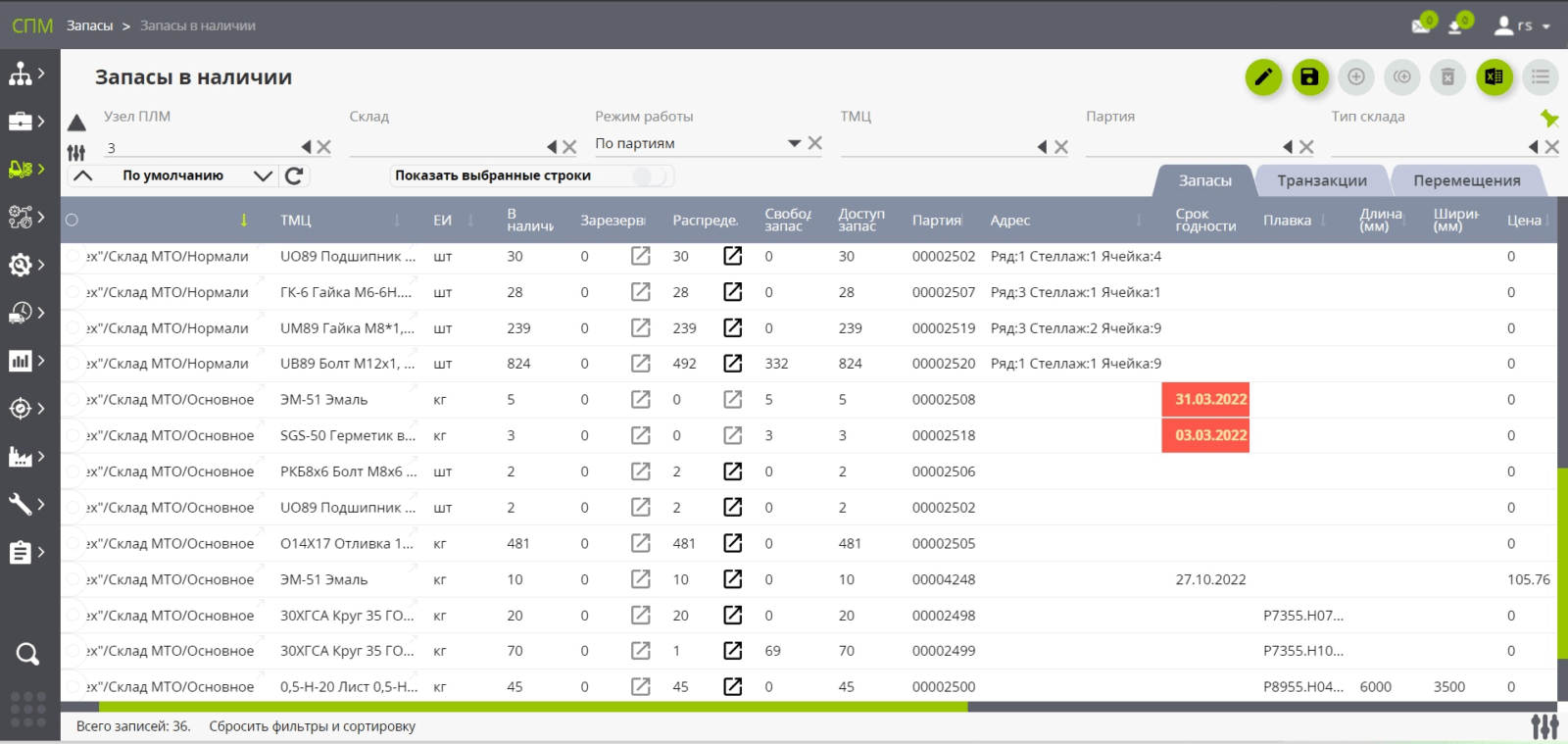

- For any actions with inventory – tracking analytical attributes and attributes:

- transaction date,

- customer's order,

- accompanying document,

- division, source / receiver,

- warehouse, source / receiver,

- quantity,

- reason for inventory movement, or reason for recording labor costs,

- batch, serial number, etc.

- Distinctive features of inventory management in SPM used in manufacturing enterprises:

- Management of MTS "as production" (planning and control of deliveries along external routes / stages) to improve the reliability and accuracy of deliveries.

- Planning and purchasing to order (for head products with their own serial numbers).

- Forming a payment schedule for the order of picking and starting production.

- Use of digital input tools (barcoding, RFID, etc.).

- Integration with automated warehouse complexes.

- The possibility of implementing the concept VMI (involving suppliers in inventory management).

Monitoring and KPI

- On-line monitoring of production / supply across the entire supply chain. By order / contract / supplier / co-op / shop / site.

- Monitoring from detailed (for the master) to summary (for the CEO), with the ability to "drill-down" to details and operations.

- Monitoring the overall synchronicity of plant/supply chain operations, visualizing the economy and operational efficiency in terms of synchronicity and timely execution of plans.

- Support for the transition to a time-based premium payment system.