JSC OKB Kristall

To share:

Тип проекта

Постановка методологии системного планирования и мониторинга производства, разработка функциональных требований, подготовка НСИ в специальном модуле СПМ — «PDM Light». Внедрение SPM (Lean ERP SCMo), сквозная кооперационная производственно-логистическая цепочка поставок двух заводов, участвующих в одних неразрывных процессах. Интеграция со смежными ИС.

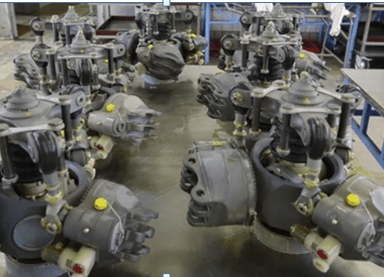

На сегодняшний день OKB Kristall в рамках научно-исследовательских работ (НИР) и опытно-конструкторских работ (ОКР), сотрудничая с ведущими самолетостроительными и двигателестроительными фирмами, реализует ряд крупных проектов по созданию перспективных топливных, гидравлических, электрических систем и агрегатов для авиационной отрасли.

Production features:

- The plant has a full technological cycle of production - from foundry to assembly and testing.

- Planning model: "development and production-to-order", "production-to-warehouse".

- A fairly large range of manufactured products, with different cycles (from weeks to months), with 10+ levels of nesting. From hundreds to thousands of items of components included in the product.

The project was initiated as part of the transformation that began at OKB Kristall (reconstruction and restructuring of the plant) in order to modernize and increase efficiency.

- Setting up a more efficient production and logistics model.

- Synchronization of information and material flows of production and procurement for orders.

- Autonomy of operational management processes, providing line and senior managers with prompt and reliable monitoring of what is happening along the entire order fulfillment chain.

- Реализация эффективной схемы взаимодействия ОКБ «Кристалл» и MMZ"VPERYOD": сквозная кооперационная производственно-логистическая цепочка поставок заводов, являющихся разными юрлицами, но физически участвующими в одних неразрывных процессах.

- Development of functional requirements — definition of the concept (methods, processes, basic requirements for the IT system).

- Подготовка НСИ – сбор, нормализация, «чистка» и выверка справочно-нормативных данных.

- Transfer of product composition management functions to the SPM. Transfer of work of employees of the plant's Chief Technologist Department to the SPM (the PDM-Lite SPM module).

- Управление спросом и планирование. Ведение прогнозов спроса и заказов клиентов, планирование производства и МТС (с упрощенными функциями управления запасами закупаемых ТМЦ и запасами в производстве). Мониторинг.

- Launch of production management. Start-up management, production batch formation, production configuration, production progress accounting, document management, including monitoring.

- Управление закупками. Управление «запуском», управление закупками в методологии SCM, включая мониторинг.

- Demand management. Setting up processes, including modeling functions — determining the possibility and timing of order fulfillment based on loading bottlenecks. Automation of modeling in the medium and long term.

Implementation of the following areas of SPM development has been started or in the near future:

- Automation of accounting functions using SPM tools for digital input (based on barcoding).

- Calculation of planned and actual production costs based on direct costs.

- Organization of an electronic archive of design and technological documentation (drawings, instructions on technical processes, etc.), with the provision of operational access to personnel directly from the SPM.

- Transfer of the production performance assessment system from monthly to daily synchronicity indicators.

- Detailed production planning and management, up to the operational level.

- Integration with related ICS, the implementation of which began in parallel with the SPM project: 1C, PDM-system (SW), digital monitoring system for equipment operation (AIS "Dispatcher").