Ust-Katav Carriage Building Plant

To share:

Тип проекта

Разработка Модели и Методологического решения: концепции и алгоритмов планирования, исполнения и мониторинга, требований к реорганизации процессов управления (в виде регламентов и процедур взаимодействия). Реинжиниринг модели управления, внедрение Системы планирования и мониторинга (SPM) производства и снабжения.

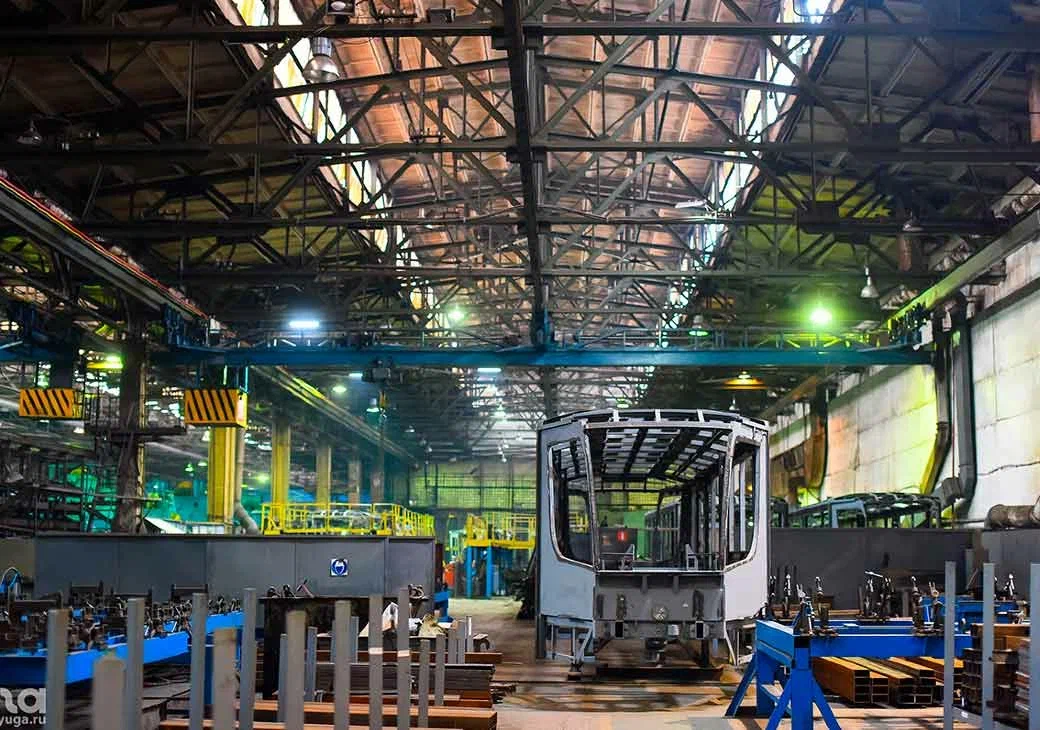

Business АО «Усть-Катавского вагоностроительного завода» ( АО УКВЗ) диверсифицирован: гражданскую продукцию предприятие выпускает еще с 19 века, а начиная с 1961г. здесь изготавливаются двигательные установки для пилотируемых и грузовых космических кораблей разных типов.

In different years of space exploration, the company has participated and continues to participate in the Energia-Buran, MIR Space Station, and ISS projects, as well as in the supply of engines and other components for SOYUZ, PROGRESS, PROTON, and ANGARA rockets.

The civil branch of UKVZ is primarily known for the production of trams (since 1901), which have always been distinguished by high quality and technical perfection. Geography of deliveries – throughout the territory of the Russian Federation and for export to several countries.

Rightstep was tasked with implementing the JMP (Planning and Monitoring System) specifically for managing the production and supply of civilian products, and this was to be done as quickly as possible – in a few months.

Project Background

SPM was needed not so much as a means of automating production, but as a system:

- supporting the "correct" management ideology,

- a management tool that should be used to ensure the timely release of lots of (new) trams.

"Quick project" was a condition set by the customer. As a" control condition " for the successful implementation of the project, it was decided to accept the need to fulfill on time orders executed specifically for cities participating in the 2018 FIFA World Cup.

Based on the accumulated experience in implementing projects for complex industries, Wrightstep suggested using a standard configuration with a ready-made management methodology and a pre-configured Lean ERP SCMo system, suitable for many machine-building industries operating in the "development-...", "production-...", "assembly-to-order" types".

The tasks were completed by the joint project team of UKVZ and Wrightstep exactly on time.

Igor Ilyin, curator of the project from the Customer:

- Passing the "staging" stage as quickly as possible — the methodology for planning and controlling the production and logistics supply chain proposed by the contractor was developed and approved as the target methodology for the work of the relevant UKVZ services;

- На самой ранней стадии, как только была проработана структура НСИ в части ведения составов изделий и их отражения на производственно-логистическую модель, сразу же были подключены службы ОГК and ОГТ для формирования начального варианта наполнения НСИ.»

Project implementation

During the project, the following processes were set up and debugged::

Management of the product's technological composition (TSI).

- The production and logistics model of the enterprise (PLM) is defined in the form of supply and configuration departments, production sites, and an assembly line detailed to work places.

- Сформирован ТСИ с детализацией «расширенная спецификация»: спецификация и «расцеховка» до уровня «участкозаход» (УЗ). Для сборочных цехов / участков УЗ – это этап сборки на рабочем месте, для закупаемых – длительность и этапы закупок.

- TSI management with regard to serial restrictions for automatic formation of order-based composition of a particular tram.

- Обеспечено хранение и просмотр на всех рабочих местах исполнителей актуальных чертежей Assembly units.

- The interaction of constructs, technologists, production and supply is organized in the form of regulations and procedures for the correct formation of TSI, excluding errors.

Mikhail Mokhov, project expert from the Customer:

«Для верификации длительности производственных циклов была проведена проверка и уточнение исходных данных с применением функциональности имитационного моделирования. Это позволило на ранней стадии внедрения СПМ привести базу данных в соответствие с «реальным производством»: с учетом пропускной способности «узких мест», размера партий запуска и специфики режима работы производственных подразделений.

Тестирование СПМ с помощью имитации позволило значительно ускорить реализацию проекта.»

Order-based planning

- Maintaining orders for the production of finished products, where each" order " is a separate tram with its own directive release date and serial number.

- Synchronous planning across the entire production and logistics supply chain with the definition of priority, launch and release dates for each manufactured and purchased item.

- Each tram of the order is operated in production separately according to its composition, determined by the order number and specific serial number.

- Планирование и управление производством осуществляется «без запасов», WIP ведется в системе в виде межучастковых поставок.

Production management

- Formation of a prioritized and synchronized inter-stage product launch/release nomenclature plan.

- Managing the launch of DSE into production.

- Launch of the DSE batch and formation of accompanying batch documents in the form of Tex.Passport and tear-off card.

- Creating a group launch of a batch of different DCS, but with the same route and the same content.

- Creating and fixing a "Site plan" on the site stand for running positions.

- Registration of inter-stage deliveries of a batch of DSE in the SPM on the basis of a completed tear-off coupon for a batch of DSE.

- Auto-closing and auto-debiting procedures have been developed to simplify accounting for "non-critical" DSE.

- Automatic recalculation of plans based on the fact of launch / release — forming a " calculated "(relative to the" directive") version of the plan.

- Automatic redistribution of the fact of deliveries according to the specified algorithms in case of a change in the manufacturing route or a change in the specification to the DSE drawings.

- Formation of work orders for piecework payment of SPM, printing according to the established reporting form for transfer to the accounting department.

Warehouse management and MTS

- Automatic formation of nomenclature plans for production needs in purchased materials and components in accordance with the product release schedule and TSI consumption rates in the context of orders and suppliers.

- Managing the purchasing process:

- Creating an order for a supplier (PO),

- Manage purchase stages.

- Manage substitutions (alternatives).

- В системе СПМ ведутся следующие основные складские операции МТС, с формированием первичных учетных документов:

- arrival by PO,

- выдача supplies and materials в производство,

- moving inventory items between warehouses (invoice requirements are generated),

- return of goods from production.

Monitoring (execution control)

- Availability of orders (for each product), by estimated and target dates;

- Synchronicity with respect to assembly production, the operation of all supplier sites and MTS, with control of the WIP in terms of its timely formation.

Andrey Grigoriev, Head of the Customer's Business Information Support Group:

«Команда «Райтстеп» работала «на опережение», предлагая методические решения для проработки. Нам всем работать пришлось достаточно «агрессивно»: обучаться, продумывать и просчитывать варианты решений, готовить НСИ (чистить, наполнять, дополнять, выверять), проверять точность планирования, формализовать новые процедуры работы подразделений…

Режим работы на проекте был весьма напряженный, но «спасало» то, что это было реально интересно, и мы работали на реальный результат. Сейчас есть четкое понимание: это было правильно.»

Project uniqueness

To date, the UKVZ SPM is the fastest project of Wrightstep company for complex installation and commissioning of a system for complex production, implemented in just 8 months.

One of the key features of the project that influenced the speed of the project is the way the TSI is formed, namely, taking into account the production and logistics model of the plant, the manufactured products and the principles laid down in the SPM.

But we managed to implement a quick project thanks to the use of not just ready-made "IT tools", but also:

- the machine-building production management methodology incorporated in the SPM system,

- strict adherence to the project implementation strategy and putting the system into commercial operation,

- thanks to the well-coordinated work of the joint project team of UKVZ and Wrightstep and the project supervision by the managers of both companies.