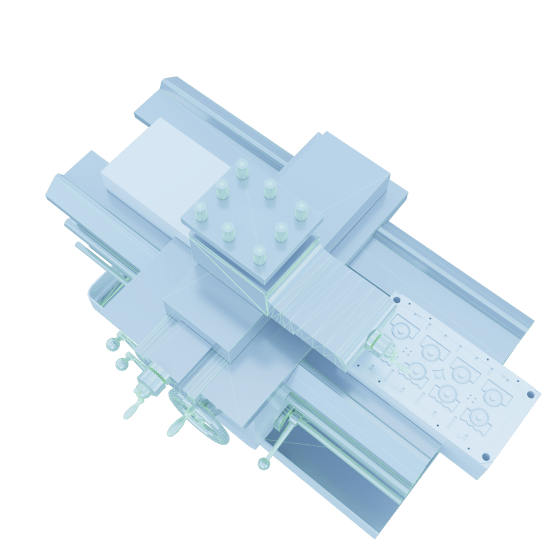

Industry specifics

Every factory we work with is unique.

Nevertheless, the factories of one industry have their own specifics, which are taken into account in our solutions and in our system.

Every factory we work with is unique.

Nevertheless, the factories of one industry have their own specifics, which are taken into account in our solutions and in our system.

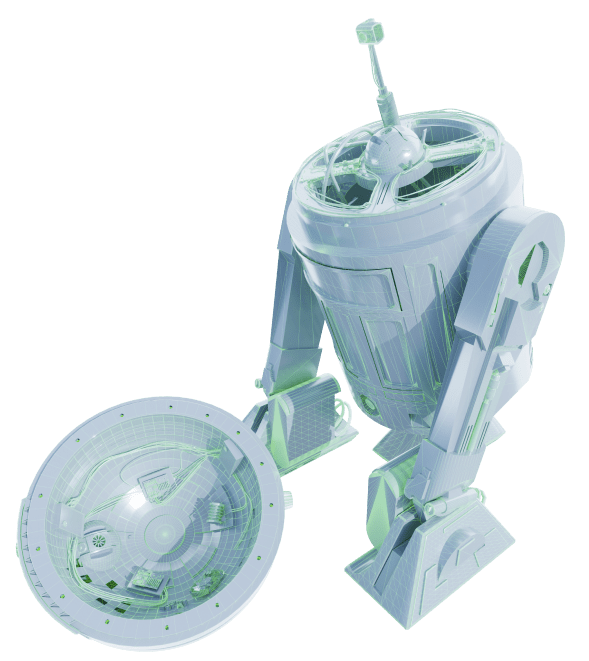

Air-space

- Features of product compositions

- Maintaining complex production and technological systems in the SPM. СИ.

- With restrictions on the series, by car. Managing design changes.

- For new / experimental products – the presence of several "vertices" for one product / layout.

- 2-level route: shop—entry - cooperative, post-operational intra-shop.

- Items of the TC, TCPT, MK, TC, or bay type.

- Technological procurement and manufactured kits and systems.

- General planning algorithm

- Independent planning (according to its product composition) of each copy by serial numbers/lots.

- Planning for assembly tasks.

- Planning taking into account KVI / ПИ.

- Complex algorithms for the distribution / reservation of stocks of materials, PKI, WIP taking into account the number of copies, contracts, work orders, directions of demand.

- Control of the aggregate and final (main) assembly

- Complex algorithms for planning the final machine assembly. Incl. and clock assembly.

- Special control objects for the execution of long-cycle assembly of aggregates / finished product — ПЗСwith the possibility of rescheduling during manufacture, changes, phased / operational configuration, etc.

- DDP Management

- The need to organize flows by compartments, by aggregates, by types of machines, "from assembly to workpiece".

- Launch management, taking into account batches, consolidation periods, QUI/PI, launch windows.

- Management of KVI/PI/inconsistencies, including different routes.

- Stocks

- Inventory management of finished DSE and along the route, including storage and inter-shop movements.

- Peregrifovka.

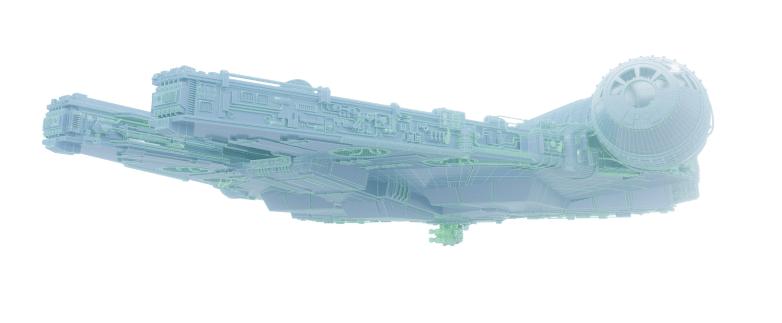

Engine building

- Different management methods and types for different workshops:

- storage

- blade shops

- machining

- mechanical assembly

- assembly shops.

- Completeness management in SGD

Instrumentation

- Constant and fast balancing of the top-level plan for releases (part of the order), capacities, finances.

- The need to quickly assess the possibility of completing a customer order.

- Management of completeness (assembly shops) with a large range of assemblies of finished products.

- A large number of alternatives for the purchased element base.

- Production of machining parts depersonalized from orders in batches.

Special vehicles

- Custom in-line production.

- Different types of planning and management for redevelopments.

- Pull scheduling for the build cycle.

- Features of planning of the beginning of repartitions: cutting, bending, welding.

- Planning for the timing of assembly lines/conveyors/ slipways.

- Managing deliveries to the assembly line/conveyor "exactly on time", "exactly in sequence".

- Separate planning of the sequence of laying cars, bodies for assembly, based on their own production capabilities, orders, chassis delivery schedule.

Metal Structures

- Forming batches of products for cutting, based on optimal cutting programs, but taking into account orders. Integration with cutting programs.

- "Competition" in the resources of procurement sites from assembly shops.

- Without inventory management in production.

Small businesses

small and medium-sized businesses

- The possibility of conducting ТСИ (PDM-Lite).

- Quick assessment of the possibility of order fulfillment with the definition of the planned date. Fast "stuffing" of urgent orders into production. Quick cost estimation based on direct costs.

- Automated scheduling, taking into account the constraints of the bottlenecks of completed / unfulfilled shift jobs.

- Quick start of production /production tasks, taking into account the unfulfilled, with (re) distribution of work by shifts, people.

- Order prioritization.

- Issuing tasks, recording the progress of production, including using mobile devices (smartphones, tablets).

Промышленное

equipment

- Evaluation of the cost and timing of product development by analogues, material intensity, labor intensity.

- Network development schedule combined with the composition of the product.

- Phased development KTD, start of production with ready-made units.

- Order-by-order planning and tracking in production.

Tooling shops,

tool shops

- Synchronization of the development process ТСИ for tooling / molds with production and procurement processes.

- Manage tooling repairs.

- Planning taking into account resource constraints — specific machines.

Ремонтные производства

- Прием заказов на ремонты, в т.ч. загрузкой из внешних ИС завода или заказчиков (ТОиР / ERP / CRM). С возможностью указания типа возврата, аналитики для распределения запасов.

- Настройка этапов (эталонных) дефектования изделия.

- Дефектование. Ведомости. Возможность фото-фиксации.

- До-определение маршрутов и составов для конкретного изделия / заказа.

- Планирование и синхронизация производства.

- Деталеделательные, мех-обрабатывающие, сборочные переделы.

- Планирование / контроль МТО и кооперации по внешним этапам / цепочкам.